top of page

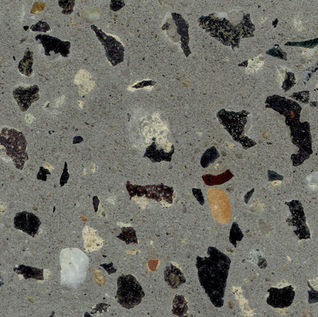

Responsibly Sourced Content | High Levels of Recycled Materials | Free of Resins & Plastics | Small Carbon Footprint

Australian Sustainable Concrete

Go As Green As You Want

✔ We replace Portland cement with industrial furnace wastes.

✔✔ We replace mined sand with recycled kerbside waste.

✔✔✔ Your choice to replace quarried aggregates with recycled brick, rubble or glass.

bottom of page